Essential details

- Place of Origin:

- guangdong

- Brand Name:

- Juli Composite

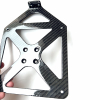

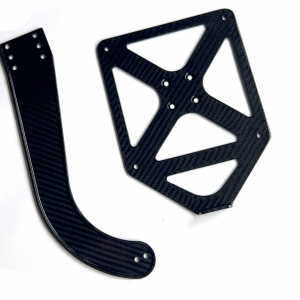

- Model Number:

- JULI CARBON CAR PART

- Application:

- car part

- Shape:

- Carbon Plate

- Dimensions:

- customizable

- Product Type:

- Carbon Fiber

- C Content (%):

- 100%

- Working Temperature:

- 0-200 degree

- S Content (%):

- 0

- N Content (%):

- 0

- H Content (%):

- 0

- Ash Content (%):

- 0

- Volatile:

- 0

- Material:

- High Modulus Carbon Fiber

- Surface:

- 3k Twill/plain Glossy/matte

- Size:

- Customer 's Requirement

- Technique:

- Autoclave

- HS code:

- 3917290000

- DENSITY:

- 1.5g/cm3

- Logo:

- Customized Logo

- Tensile Strength:

- 3500MPa

- Raw material:

- T700S

- Usage:

- racing cars

Supply Ability

- Supply Ability

- 5000 Piece/Pieces per Week

high performance custom carbon fiber car parts by autoclave process

Product Description

Specification

TECHNICAL DATA SHEET | ||||||||

Manufacturing Method : | Carbon fiber Compression Moulding Process | |||||||

Raw Materials : | Carbon fiber , Epoxy | |||||||

Diameter Range O.D. | make to order | |||||||

Wall Thickness | 0.5 to 10mm | |||||||

Length : | 3.5 Meters Maximum | |||||||

Wall Thickness | 0.5 to 10mm | |||||||

Colors : | RAL Code Or Black | |||||||

Water Absorption | < 1,5w- % | |||||||

Denisty | 1.5g/cm3 | |||||||

FIBER TYPE | HS Carbon | HM Carbon | ||||||

Stiffness | 90-100 Gpa | 120- 180 Gpa | ||||||

Bending Strength | >600 Mpa | >500 Mpa | ||||||

Tensile Strength | >650 Mpa | >550 Mpa | ||||||

Tensile Strength | >1.5g/cm3 | >1.5g/cm3 | ||||||

Denisity | ||||||||

Regular Lay up of product

0 ° ORIENTATION

If a part will only be loaded in one direction it’s ideal to have all the fibers oriented in that direction. Pultruded rod and tubing are examples of a part that contains only 0° fibers

If a part will only be loaded in one direction it’s ideal to have all the fibers oriented in that direction. Pultruded rod and tubing are examples of a part that contains only 0° fibers

90° ORIENTATION

As previously mentioned, 90° layers are often added to tubes to make them more resistant to buckling and crushing. High concentrations of 90° or “hoop” layers can also be found in pressure vessels.

+/- 45 ° ORIENTATION

45° layers serve different purposes depending on the application. You’ll almost always see a +45° paired adjacent to a -45° layer.This is to keep the laminate “balanced” and from forcefully twisting when loaded.

The Manufacturing Process

Autoclaving is a process that ensures the highest quality of carbon fiber reinforced polymer (CFRP) composite structures used in

aviation. During the autoclave process, consolidation of prepreg laminas through simultaneous elevated pressure and temperature

results in a uniform high-end material system. This work focuses on analyzing in a fundamental way the applications of pressure

and temperature separately during prepreg consolidation. A controlled pressure vessel (press-clave) has been designed that applies

pressure during the curing process while the temperature is being applied locally by heat blankets. This vessel gives the ability

to design manufacturing processes with different pressures while applying temperature at desired regions of the composite.

Company Profile

VR